Blog 8

This post will outline the team's current progress with the project. From March 11th to March 23rd, the team encountered a problem with the project. The team initially had a meeting with the VP of engineering at Sulzer to finalize the proposed design documents. After review, it was expressed to the team that the document was sufficient and necessary parts needed to be machined or purchased. However, an engineer at Sulzer reached out to the team and expressed an issue with the initial problem statement given to the team on March 18th. It was stated that the initial expressed RPM range given to the team was incorrect and the new RPM range was higher by 10 percent. The team then had to recalculate the initial data to the new specifications. After finalizing the team's calculations, the team resubmitted an updated design proposal to the VP of engineering. However, the team did not receive feedback or meeting times. The team continuously reached out to Sulzer to set up various meetings with the VP of engineering and the engineering team but could not establish communication with Sulzer. On the week of April 4th, the team was able to meet with the engineering team at Sulzer, but additional concerns and information were given to the team. Even though the team communicated the timeline of the capstone class to Sulzer, it was stated that a revision to the document needed to be done based on formatting. With the given situation, the team reached out to Dr. Agrawal for advice on how to approach the current situation. The professor encouraged the team to construct a scaled-down prototype model of how the initial system will behave. On April 8th, the team purchased 2-inch deep groove ball bearings and a split pillow block bearing housing as sss is if the spring/mass can extrude out of the section on the shaft and trip the overall model as shown in Figure 5. Overall, the team is not satisfied with the initial project given by Sulzer due to the lack of communication and professionalism displayed by the company. Given the short amount of time, the team is satisfied with the effort displayed to pivot to a new design concept. The team will continue to construct the final prototype model for the final presentation.

Figure 1: Split pillow block

bearing housing

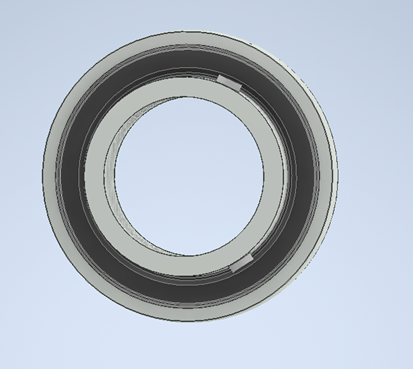

Figure 2: Deep groove ball bearing

Figure 3: DC motor

Figure 4: Design Concept

Figure 5: Spring/mass system

Comments

Post a Comment